Mechanical Convection Oven (ESP400 Series)

The ESP 400 Series Mechanical Convection Oven is a compact and economical industrial oven that offers reliable performance with horizontal airflow for excellent temperature uniformity and is ideal for applications with multiple product levels arranged to allow air to flow horizontally from side to side. The ESP 400 Series incorporates Blue M's single-pass airflow system, which allows incoming air to pass over the heaters and through the work chamber only once if desired, allowing for rapid cooling or rapid venting of non-hazardous fumes. Whether you're conducting research or manufacturing small batches, the ESP 400 Series Mechanical Convection Oven is the perfect choice.

Whether you're conducting research or manufacturing small batches, the ESP 400 Series mechanical convection oven is the perfect choice.

Standard Mechanical Convection Oven Series 146

The Blue M 146 standard mechanical convection oven is ideal for a variety of laboratory and light industrial applications, including ASTM testing, epoxy curing, moisture curing, UL testing, aging of electronic components and devices, and many other testing processes or requirements. This standard mechanical convection oven includes features such as Eterna heating elements and single-pass airflow control. It is ideal for a wide range of laboratory and industrial applications.

Mechanical Convection Oven (Batch Series)

Blue M Class A batch ovens are mechanically convection electric chambers that include the safety features recommended in NFPA Bulletin 86 as standard for processing alcohol, solvent mixtures, or other volatiles. The Class A oven chamber design allows the element temperature to significantly exceed the autoignition point of some flammable materials. However, this is mitigated by maintaining a non-explosive mixture through the use of higher-than-normal extraction rates. Increasing the heating element power compensates for this extraction factor. A negative pressure is maintained in the working chamber, ensuring that all hazardous vapors are expelled through the extraction duct and not through the oven door, fan shaft seal, or openings.

Blue M Batch Series Class A mechanical convection ovens are complete systems. No additional equipment or custom procedures are required to meet NFPA 86 recommendations for processing hazardous workloads.

Ultra-Temp Oven (IGF/CW Series)

Temperature 15°C (27°F) above ambient to 704°C (1,299°F)

Interior Volume: 1.6 to 24.0 cu.ft.

Controller: Watlow PM Optional: Watlow F4T or Yokogawa UP55A

Available Configurations: Standard air chamber, inert gas (reduces temp to 593°C [1,099°F])

Lab Oven (LO Series)

The Blue M LO Series mechanical convection laboratory oven is designed for laboratory applications such as moisture drying, curing, baking, aging, and general testing. These convection ovens utilize horizontal airflow for greater temperature uniformity and high-quality components to ensure years of reliable service. They also offer adjustable overheat protection to prevent damage to the oven or its load.

Custom Conveyor Ovens

At Gruenberg, we pride ourselves on being a leading manufacturer of custom conveyor ovens in a wide range of sizes and temperature specifications. Each Gruenberg conveyor oven can be custom-built to meet the most stringent customer specifications, ensuring a perfect fit for a wide range of applications.

What sets Gruenberg custom conveyor ovens apart? Their flexible, modular design, perfected through years of industry experience. As production increases, our ovens are easily tailored to your needs by adding our standard 1.83 m units to your system to expand your oven or create separate heating and cooling sections within your continuous process.

Pharmaceutical ovens and sterilizers

Pharmaceutical ovens are specialized industrial ovens designed for critical processes in the pharmaceutical industry. They provide controlled heating environments for a wide range of applications, including:

- Drying: Removal of moisture from pharmaceutical ingredients, active compounds and finished products.

- Sterilization: Elimination of microorganisms and contaminants to ensure product safety and purity.

- Depyrogenation: Destruction of pyrogens (fever-causing substances) from glassware and equipment used in the manufacture of pharmaceutical products.

Class A Truck-In Ovens for Solvent Venting

Gruenberg Oven Company designs and manufactures a complete line of standard and custom Class A truck ovens to suit a variety of thermal processing applications up to 1200°F. Our Class A industrial ovens are ideal for the following applications:

- powder coating

- drum heating

- ageing

- core hardening

- drying

- preheating

- healing

- component testing

Truck-in ovens

Gruenberg autoclave curing ovens feature a flexible design, ideal for composite materials with complex contours, shapes, and sizes. These ovens are used to cure advanced composite materials such as carbon fibers, ceramics, Kevlar®, Nomex®, thermoset and thermoplastic resins, epoxies, aramids, glass fibers, and nanomaterials. Standard and custom sizes are available to fit any workspace and application..

Top Loading Ovens by Gruenberg

Gruenberg, a leading manufacturer of industrial ovens, offers specialty top-loading ovens designed for a variety of processes, including recocido , preheating, baking, drying, curing, aging and more.

Known for their rugged durability, these top-loading furnaces are especially well-suited for oil and gas applications, and Gruenberg offers a top-loading design specifically for this industry. Choose from our standard and custom options to suit a wide range of processing applications.

Effortless loading and unloading

Our top-loading industrial ovens feature counterbalanced top doors, making manual loading and unloading quick and easy. Quality CHIL construction ensures minimal heat transfer from the chamber to the exterior, resulting in greater energy efficiency. Their modular design allows multiple units to be connected for more extensive product testing.

Granulation Dryers & Pharmaceutical Tray Dryers

Gruenberg designs and manufactures granulation drying equipment ideal for drying pharmaceutical trays. It is constructed with a welded steel frame for long-lasting reliability. All interior surfaces are made of 100% continuously welded stainless steel for quick and easy cleanup. Steam, hot water, or electrically heated granulation dryers reach temperatures up to 90°C. Gruenberg granulation drying equipment is available with two standard types of circulation systems: controlled recirculation and single-pass systems.

Key specifications

- Temperature range: typically up to 85 °C (185 °F)

- Uniformity: ±2°C

- Chamber size: 15 to 800 cubic feet

Depyrogenation Ovens & Sterilizers

Gruenberg manufactures standard depyrogenation ovens and designs custom ovens based on your needs. Our sterilizers comply with cGMP standards and offer more standard features than competing models. Our depyrogenation ovens are designed for the sterilization and drying of pharmaceutical products. These product lines are offered in various configurations, including laboratory, booth, truck, pass-through, and continuous, to meet a wide range of analytical needs.

All Gruenberg sterilizers and depyrogenation ovens are customized to your specific temperature and cycle time requirements. HEPA filters, along with a continuous helical arc-welded interior, prevent contaminants from entering the sterilizer, ensuring optimal performance. Efficient airflow management systems also provide exceptional temperature uniformity for your process.

Multi-Truck Steri-Dry™ Sterilizer

The Gruenberg Steri-Dry™ dry heat sterilizer for laboratory animals offers the animal science market equipment for sterilizing habitat cages using dry heat. Gruenberg dry heat sterilizers are designed for laboratory animal applications.

Key specifications

- Temperature range: 400°F maximum

- Chamber size: 96 to 362 cubic feet

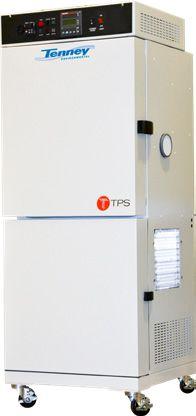

Tenney y Lunaire

They have one of the most complete lines of environmental test chambers and rooms, both standard and custom, in the industry.

Known for their innovative engineering and design, rugged construction, and superior performance, Tenney and Lunaire test chambers are designed to meet all of your temperature, humidity, altitude, and vacuum testing needs.

TJR/TUJR (Reach in Temperature Cycling Chamber)

Temperature:

-68°C to +180°C

Energy: 120V

Size: 1.2 cu.ft.

Control: Watlow F4T

Environments: Temperature Only

T2 (Reach in Temperature Cycling Chamber)

Temperature: -68°C to +180°C

RH: 20% to 95%

Size 2 cu.ft.

Control: Watlow F4T

Environments: Temp or Temp / Humidity

TC (Reach in Temperature Cycling Chamber)

TEMP: -68°C to +180°C

RH: 20% to 95%

SIZE: 10 to 64 cu.ft.

CONTROL: Watlow F4T

ENVIRONMENTS: Temp or Temp / Humidit

C-EVO (Reach in Temperature Cycling Chamber)

Temp.: -68°C to +180°C

RH: 20% to 95%

Size: 10 to 64 cu.ft.

Control: Smart One 1.2

Environments:

Temp or Temp / Humidity

Walk In (Panelized and Solid Construction)

TEMP : -68°C to +200°C

RH: 20% to 95%

SIZE 316 cu.ft. and up

CONTROL Synergy Quattro

Thermal Shock (Vertical or Horizontal, 2 Zone)

TEMP: -73°C to +200°C

BASKET SIZE:

22 to 8.32 cu.ft.

CONTROL:

Synergy Quattro

Empiece con el cliente – descubra lo que quiere y déselo.